TRANSFORM YOUR PIPELINE INFRASTRUCTURE

Advanced Non-Metallic Rehabilitation Solutions for Conventional Pipelines

THE CHALLENGE OF AGING PIPELINE INFRASTRUCTURE

Corrosion

Metallic pipelines suffer from internal and external corrosion, leading to leaks, reduced capacity, and safety risks

HIGH REPLACEMENT COST

Traditional replacement requires extensive excavation, traffic disruption, and significant capital investment

OPERATIONAL DOWNTIME

Conventional repair methods result in extended service interruptions affecting business continuity

Environmental Impact

Excavation-based methods cause environmental disruption and increase carbon footprint

Our Non-Metallic Rehabilitation Solution

Advanced trenchless technology that restores pipeline integrity without excavation

TRENCHLESS TECHNOLOGY

SLIPLINING RTP

Insert reinforced thermoplastic pipes (RTP) inside existing metallic pipelines for high-pressure applications up to 3500 PSI

- Corrosion-resistant thermoplastic material

- Quick installation with minimal downtime

- 50+ year service life expectancy

TRENCHLESS TECHNOLOGY

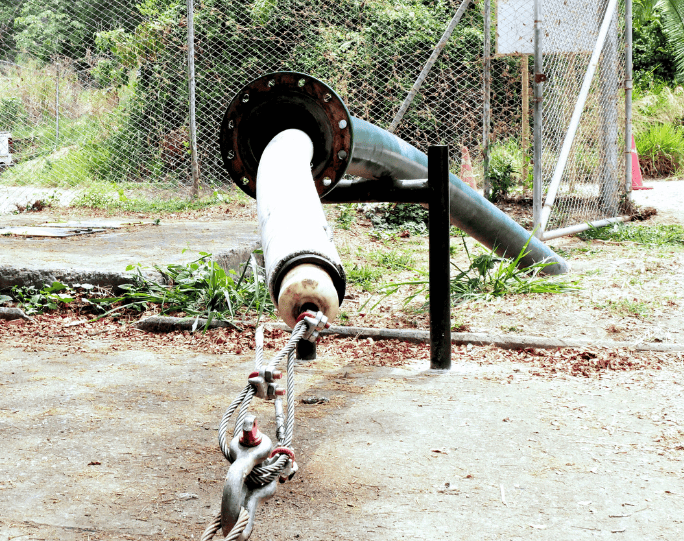

PRIMUS LINE®

Primus Line® is a trenchless technology for pressure pipe rehabilitation. It uses a flexible aramid-reinforced liner and specialized connectors installed inside the existing pipeline, restoring integrity and extending service life without excavation.

- Minimum excavation requirement

- Maintains original flow capacity

- Resistant to chemicals and temperature.

TRENCHLESS TECHNOLOGY

COMPRESSION FIT

CompressionFit is an HDPE pipe lining technology (ASTM F3508) where a slightly larger HDPE pipe is temporarily reduced in diameter, pulled into the host pipe, and then allowed to expand tightly against its inner wall—creating a new, fully structural composite pipe inside the existing one.

- Minimum excavation requirement

- It can maintain the original flow capacity

- Resistant to chemicals and temperature.

Applications & Industries

Oil & Gas Pipelines

Hydrocarbon transport systems

Natural Gas Distribution

High-pressure gas networks

Water & Wastewater

Municipal infrastructure

Power Generation

process water systems

Infrastructure

Underground utilities protection

Why Choose Non-Metallic Rehabilitation?

1

2

3

4

5

6

Trenchless technology

Our Rehabilitation Process

Inspection & Assessment

Advanced diagnostic tools including drone technology and internal cameras to evaluate pipeline condition

Engineering Design

Custom solution design based on pipeline specifications, operating conditions, and performance requirements

Preparation & Cleaning

Internal cleaning and surface preparation to ensure optimal adhesion and installation conditions

Installation

Precision installation of non-metallic liner or reinforcement system using trenchless technology

Testing & Certification

Comprehensive pressure testing and quality assurance to meet industry standards and specifications

Monitoring & Support

Ongoing integrity management and maintenance services to ensure long-term performance

Integrity management

Advanced Technology

DRONE-GUARD

PLATE-GUARD

Download our complete technical brochure

- Complete solution portfolio overview

- Technical specifications and standards

- Installation methodology details